Grouting Types & Applications: Advantages & Process

Table of Contents

- What is Grouting?

- Types of Grouting?

- About Cement Grouting

- Uses of Cemenet Grouting

- About Chemical Grouting

- Process of Chemical Grouting

- About Structural Grouting

- Uses of Structural Grouting

- About Bentonite Grouting

- Uses of Bentonite Grouting

- About Bituminuos Grouting

- Uses of Hot Bitumen Grouting

- About Resin Grouting

- Uses of Resin Grouting

- Advantages of Grouting

- Applications of Grouting

- Process of Grouting

- Grouting Applicable Process

Generally, a fluid prepared from a mixture of sand, cement, water, or a liquid prepared from a mixture of chemical substances for waterproofing is called grout. But gravel is also used in grout along with sand, cement, and water to strengthen large areas like the core of concrete blocks.

Grout materials are used in a variety of ways to strengthen building structures during construction. such as pile foundation, ground anchor, under reaming, dam construction, road construction, etc. Apart from this, grout is also used to overcome the problem of water seeping into the roof and exterior walls of the building and to fix the tiles to the floor and walls. The method of using grout material in various ways in construction work is called grouting. Let's see detailed information related to grouting.

What is Grouting?

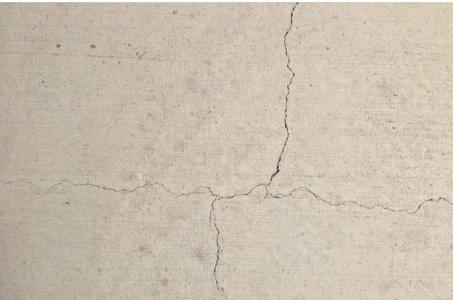

The method of using grout to repair cracks in concrete, fill gaps in tiles, seal joints and stabilize the soil, etc. is called grouting.

Grouting is used to provide additional strength to a building's foundation and structure. It is also used to repair cracks in concrete, fill gaps in tiles, seal joints, and stabilize soils.

Types of Grouting

In building construction, the material of grouting is prepared in different ways depending on the pile foundation, ground anchor, under reaming, dam construction, road construction, and waterproofing of the building, etc. The types of grouting are as follows:

1) Cement Grouting

Cement grouting is used for high permeability land, for which the grout is prepared using water, sand, and cement.

Uses of Cement Grouting

Cement grouting is used to provide deposit/stabilization and strengthen to a wide variety of structures such as bridges, marine applications, dams, and rock anchors.

The grout material is then injected in liquid form with high pressure to fill the hole in a specified radius around the area used for grouting. The viscosity of the grout material is increased by reducing the water-cement ratio as required. The grouting process is then completed by making a second hole between the primary holes to ensure complete grouting of the area.

2) Chemical Grouting

Chemical grouting is a form of permeation grouting. This type of grouting mix usually includes acrylamides, polyurethanes, acrylates, epoxy, and sodium silicates.

There are two main processes of chemical grouting::

Two-shot Process

In this process, the pipe is inserted into the ground through a drill. After this, the chemical material is pumped through the pipe in such a way one is followed by another into the soil. So that in the process of a chemical reaction the soil can take a solid form at a rapid speed.

One-shot process

In this method, a chemical mixture of grouting material is prepared in advance and then poured underground. This process takes time for the structure to harden. A one-shot process of chemical grouting is used for boreholes.

3) Structural Grouting

A structure is constructed at the site to be mined. Structural grouting is used to fill the gaps between concrete and rock structures and fill the voids between mined materials. Apart from this, structural grouting is also used to fill cracks in rocks and joints of rocks in underground tunnels.

Uses of Structural Grouting

Structural grouting is commonly done in tunnels and underground structures.

4) Bentonite Grouting

Bentonite is the major component in drilling muds or fluids used in rotary drilling. The suitability of sodium bentonite as a grouting material is 15 times its dry volume when hydrated. Due to its swelling and gel-like permeability property, it is suitable for filling gaps between the casings.

Use of Bentonite Grouting

Sodium bentonite grout is typically used for sealing and covering unutilized wells, sealing of earthen structures, and water-proofing.

Due to the high montmorillonite (an aluminum-rich clay mineral of the smectite group, containing some sodium and magnesium.) content and the ability to swell on water absorption, this grout is suitable for grouting of annular space between boreholes created during good construction.

5) Bituminous Grouting

Hot bitumen grouting is a special type of grouting in which molten hot coral is used as the grouting material.

Uses of Hot-Bitumen Grouting

Hot-bitumen grouting is often used to cut high volumes of underground water flow. The key characteristic of hot bitumen grout is its temperature-dependent viscosity.

6) Resin Grouting

Epoxy grouts are also known as reactive resin grouts. This type of grouting material is made from a cement-based mixture. It is not waterproof but has the ability to absorb water when wet.

Uses of Resin Grouting

Due to its stain resistance, durability, and hygienic property, it is suitable for most usable places such as hospitals, worktops, kitchen counters, and food production facilities. It is best for sealing ceramic tiles used for floors and walls.

Advantages of Grouting

- Grouting can be used on all types of land.

- In building structures, there is no vibration during grouting or can be controlled so that there is no possibility of deformation of the structures.

- Grouting improves the structure of the site.

- Grouting proves useful in slab jacking i.e. lifting of deformed structure, bearing the load on the structure, etc.

- Grouting is useful in filling the cracks in the walls, pillars.

- It helps in controlling groundwater flow, leakage, and harmful waste materials.

Applications of Grouting

- It is used to repair machine foundations, base plates, load-bearing, and pillar joints in prefabricated structures.

- Grouting is used to fill gaps, cracks in concrete structures.

- Used for repairing footpaths and the ground under foundations.

- Defects in masonry and cracks in concrete are repaired by grouting.

- Used in soil stabilization.

- Used to control water leakage in mines, tunnels, dams, underground structures.

- Grouting is used to repair unusual and difficult geotechnical and structural problems

- Used to aid in the excavation process.

Process of Grouting

The basic arrangement of grouting is ensured by mechanical techniques like high-pressure water jetting, breakers, blast cleaning, scribbles, etc. After this, the concrete layer has to be soaked continuously for 2-6 hours with clean water. This creates a dry layer of water-absorbed concrete during the grouting process.

Mixture preparation

surface spread/disperse ratio

Water: Powder = 0.14 to 0.16 by weight (4.2 liters to 4.8 liters of water per 30 kg bag).

the ratio of surface mix

Water: Powder = 0.12 to 0.14 by weight (3.6 liters to 4.2 liters of water per 30 kg bag).

Mixing equipment

Mix the grout powder with water in the correct ratio using an instrument with a low speed (maximum 500 rpm) electric drill, so as not to allow too much air to enter the mixture.

Pour about 80 to 90% of the water into the mixing drum. Then add the remaining water.

Depending on the desired consistency and flowability, the mixing ratio can be adjusted. Do not use a concrete tilting mixer.

Application Process

- Immediately pour the grout mixture onto the prepared surface so that the displaced air in the grout can easily escape, otherwise, air bubbles trapped in the grout will hinder the firm grip on the grouting surface.

- During grouting wet porous substrate saturated surface, grouting base plate, etc in dry condition, ensure that constant and sufficient pressure is maintained to keep the grout flowing.

- To ensure that the grout is evenly spread over the surface and used to strengthen the surface hold. Use grout mixture to pour the grout as quickly as possible (within a maximum of 15 minutes).

Upto 25% OFF On Home Painting!

* Share details for Free Online-Quotation

ONE year service warranty